Are you noticing a decrease in welding cell efficiency? This may well be caused by friction in your wire circuit, slowing down production and ultimately reducing revenue. Wire Wizard’s wire feeding products save both cost and time by eliminating all friction, creating a smooth and efficient transport system. Our solutions are compatible with any welding robot brand, any type of drum or spool, and any type of wire feeder.

About Our Products

Wire Wizard is your wire-feed-solution to connect anything to everything

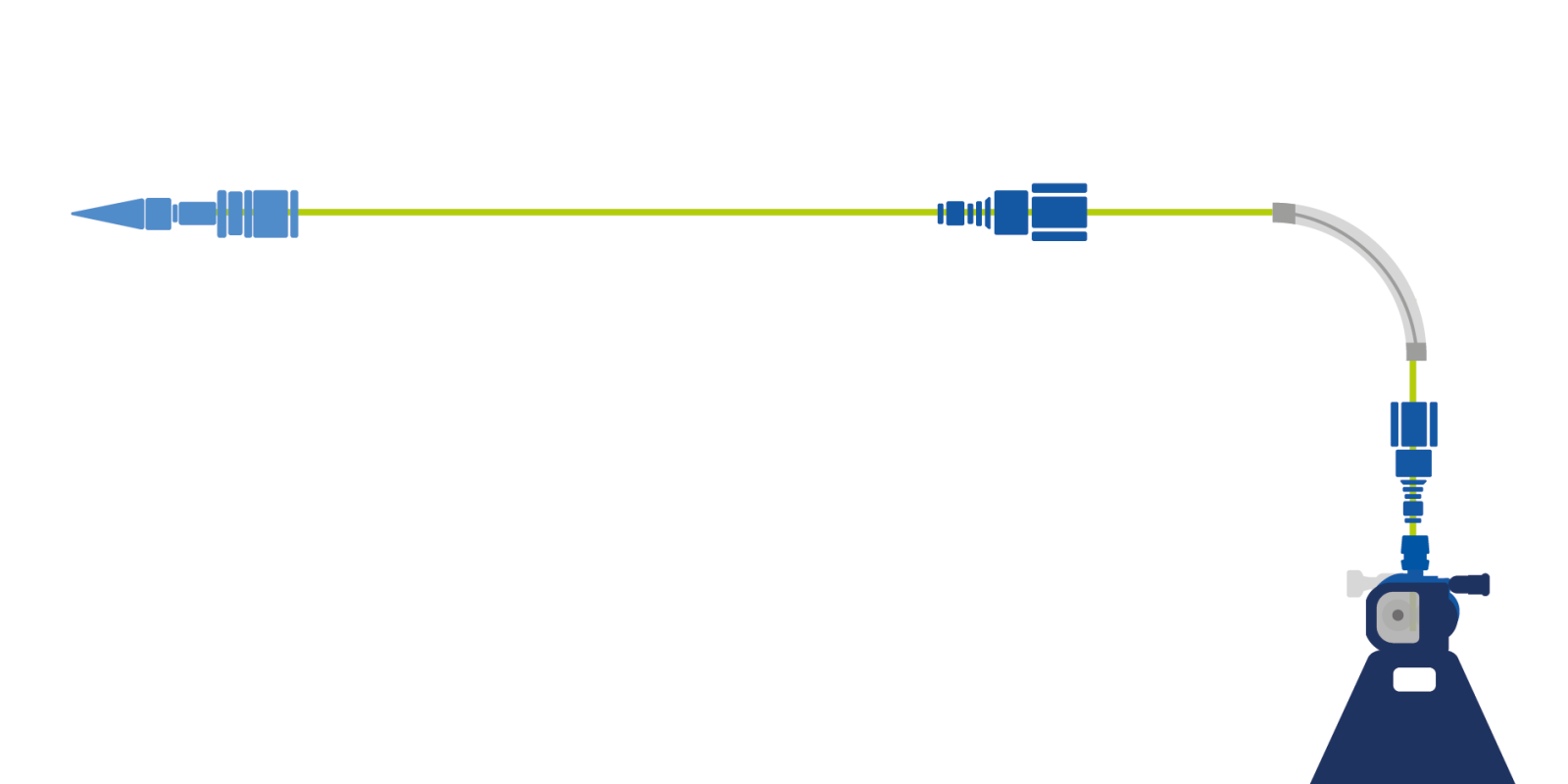

Frictionless bends

Most friction in wire setups comes from bends in the wire circuit, causing production stops and other difficulties throughout the welding process. But not to worry.

We provide smooth wire feeding for any setup with Wire Guide Modules®, which can be connected with ease. They create frictionless bends from 45º to 180º and offer options for extra tight bends.

Short and long distance feeding

Placing wire drums close to or far away from your robot cell can be a challenge. When a long cable run is used, the Pneumatic Feed Assist provides a frictionless ‘push-pull’ solution. It feeds wire over 46 meters (150 ft) as well as over short distances, and can also be used for Submerged Arc Welding.

Connectors

We offer connectors for every type of cone, conduit and wire feeder in the welding industry. All of our connectors are equipped with Quick Exchange (QE) features, simplifying and speeding up wire changes, conduit replacement and cleaning.

Find them here:

Other wire feeding basics

Any curvature in the wire from both spools and drums can be corrected with our wire straightening products (small, medium and large). For wires of all types and diameters, we offer high-quality conduits.

Drum handling is made easy with our lifter and heavy duty dolly, and we offer unbreakable cones and covers for all available drums. When changing drums, production downtime can be avoided using non-stop wire dispensing.

Wire feeding from A-Z

Plug and play, as easy as lego

Submerged Arc Welding (SAW)

Wire Wizard has a separate product line suitable for the large welding wire diameters (2.4 to 5mm) used in SAW. Incorporating extra flexible conduits, heavy duty connectors, large Wire Guide Modules for frictionless bends and more, we guarantee smooth wire feeding in the most demanding conditions.

Click here to explore our full range of SAW products.

Welding equipment

In addition to specialized solutions, we also provide basic welding equipment. Our range of torch products include standard torches, consumables, and liners.

For any welding process, we are your go-to partner for traditional anti spatter. But we also present a revolutionary new way: spatter shield is a fluid atomized into the shielding gas, creating a protective layer around spatter during mild steel and stainless steel welding.

Need help?

Explore our full Wire Wizard product line here or contact us via sales@wire-wizard.eu for personal advice.