Products

Non-Stop Wire Accessories

Enhance your Non-Stop® Wire Dispensing System with purpose-built accessories designed to streamline wire changeovers, improve feed reliability, and reduce maintenance downtime. Each tool is engineered to support high-performance robotic welding environments.

Butt Welder Docking Station

A complete solution for joining wire ends, featuring a resistance butt welder (available in 110V or 220V), wire parters for flush cuts, and a wire gage block to verify wire diameter. This station ensures fast, clean wire transitions with minimal operator input.

Wire Parters

Included with the docking station, these tools deliver precise, flat wire cuts essential for successful butt welding.

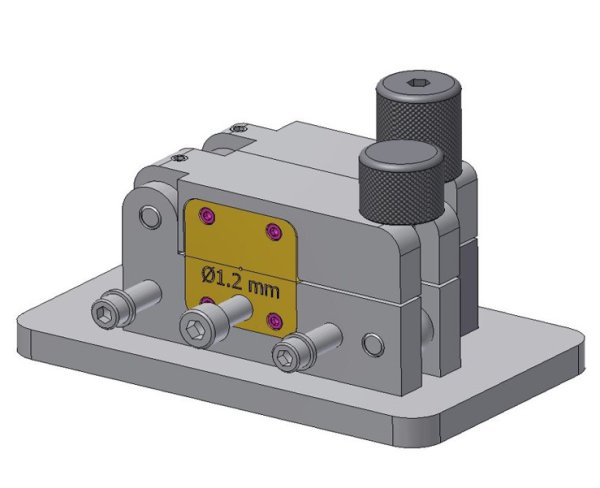

Wire Sizer

Removes burrs from welded joints to ensure smooth feeding through the wire guide system. Available in multiple sizes to match common wire diameters.

Wire Gage Block

Verifies the diameter of cleaned wire joints (.035”, .045”, .052”, and .062”) to prevent feeding issues and ensure consistent weld quality.

Mounting Adapters

Choose between rigid and swivel adapters for mounting Wire Guide Modules. The swivel version allows 360° rotation for flexible wire routing.

Feed Assist Adapter

Mounts the Wire Pilot® Pneumatic Feed Assist to the system, improving wire delivery in long or complex feed paths.

These accessories are designed to integrate seamlessly with the Non-Stop® system, helping you maintain continuous production and reduce manual intervention.